A Look into the Workshop

= Mandonator™ Serial #10 ===

This instrument was commissioned by Dennis H.

The options he chose are:

- 4 strings with standard 13.875" mandolin scale

- Palo Escrito rosewood body with Camitillo rosewood binding

- No cutaway

- Two round soundholes

- Ebony fingerboard

- White mother-of-pearl dot position markers

- Snakehead shape headstock with Palo Escrito veneer

- Ebony saddle

- Gotoh 510 Mini tuners

- Cast James tailpiece

Standard features include:

- Spherically arched back

- Mahogany neck

- Radiused fingerboard

- Spider bridge and resonator cone

- Bone nut

Parts for Mandonator™ 10 are gathered together in its dedicated shelf drawer: rosewood body wood, neck and fingerboard blanks, binding, tuners, and tailpiece. The rosewood has had a first-pass thicknessing. After final thicknessing, I'll bookmatch and join the front and back plates, then bend and join the sides.

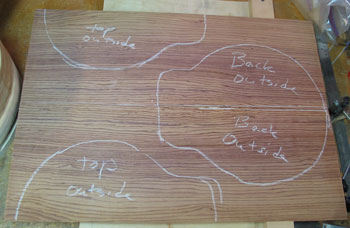

The two pieces for the back and front of the body will be bookmatched, and the outlines of the halves of each are drawn on the wood in preparation for cutting and joining.

One of the palo escrito side pieces is on the bending form jig. You can't really see the wood; it's sandwiched between two heat blankets and a heat conducting strip of metal. You can also see the edges of a piece of white parchment paper which has been added to alleviate the palo escrito's tendency to leak resin when heated.

The sides are bent and ready to be joined.

Here's what the front (on left) and back look like after their halves have been joined and bracing added to the back.

What's that -- a slinky? Nope, the lining is being glued to the sides, and all those white rings are clamping them together while the glue sets.

I made the ring clamps from a sturdy PVC pipe by cutting the pipe up into rings and then slitting them open. You can also see the end blocks which join the two side pieces.

With the linings and endblocks for the side frame of the body done, the pieces of the body are nearly ready for assembly. Any residual glue will be cleaned up, and the raw edges of the side frame sanded flat and clean in preparation for attaching the top and back.

The top is attached and trimmed, and the next step is to cut the opening for the resonator. The blue tape and nail provide alignment for a jig that I use to cut the opening.

And here's the result. the white circle is a ledge where the edge of the resonator cone will sit.

I always enjoy this stage of construction. The body is really starting to look like a Mandonator™! It still needs binding, and I'll start working on the neck and neck joint.

These are the necks, in progress, for instruments 9, 10, and 11. I've installed the graphite truss rods, created the tenons for the body joint, and attached the headstock veneers. The head and heel shapes have been roughed in. Meanwhile, I've been slotting the fretboards for these necks. Next in the process is to inlay the headstocks and fretboards. After that, I'll complete the fretboard shaping, install frets, and prepare to attach them to the necks.

This shows the nice contrasting binding on the body, and the inlay on the headstock. The fingerboard has frets and inlay and is ready to be attached to the neck.

Here's Dennis's Mandonator™, strung and playable, but still in the "white." It sounds wonderful! It's now ready for a lacquer finish to be applied by Addam Stark. The coverplate in this photo has not been plated yet. It's my own new design, and I just received the first batch from the metal worker. This one will get nickel plating.

Mandonator™ 10 has been completed! You can see photos of the finished instrument on its Gallery page.